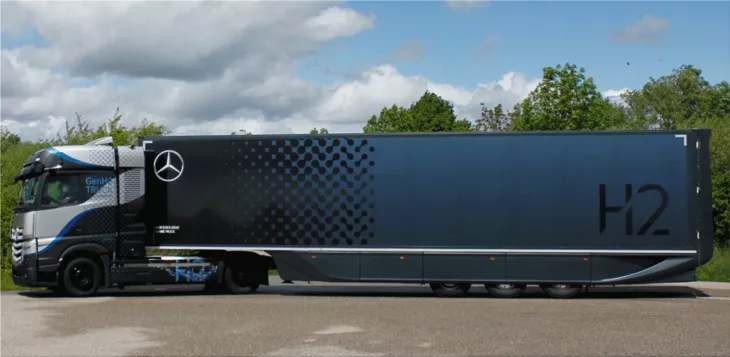

Daimler Trucks relies on hydrogen-based fuel cells to electrify its trucks for flexible and demanding long-haul operations. The goal is a range of up to 1,000 kilometres and more without a refuelling stop. The truck manufacturer began intensive tests of the first new, further developed prototype of its Mercedes-Benz GenH2 truck, which was presented in 2020, at the end of April - and thus reached an important milestone on the way to series production.

The developers at Daimler Trucks put the fuel cell truck through its paces. The broad test series, which is extremely demanding for the vehicle and components, focuses on continuous use, different weather and road conditions and various driving manoeuvres, among other things. Daimler Trucks' development plan provides for tests on public roads before the end of this year. The start of customer tests is planned for 2023 and the first series of vehicles, the GenH2 Truck, is to be handed over to customers from 2027.

The development engineers at Daimler Trucks designed the GenH2 Truck to meet the same durability requirements of the vehicle and components as the comparable conventional Mercedes-Benz Actros. That means 1.2 million kilometres of mileage, ten years of operation and a total of 25,000 operating hours. This is why the GenH2 Truck - just like every new generation of Actros - has to pass extremely demanding tests. In the first few weeks of the test alone, the vehicle had already covered hundreds of kilometres under continuous load on the roller dynamometer and underwent numerous extreme practical situations, such as emergency braking and driving on the curb on the test track.

The GenH2 Truck is a completely redesigned vehicle with completely new components, to which the developers paid special attention during the tests. These include the fuel cell system, the fully electric drive train and all associated systems such as the special cooling. The individual weight of the new components and their respective position in the vehicle also has an impact on the driving characteristics of the truck. As a result, for example, when the truck vibrates due to uneven roads and, especially in extreme situations, different forces act on the truck than with conventional vehicles.

Daimler Trucks prefers liquid hydrogen because the energy carrier in this physical state has a significantly higher energy density in relation to volume than gaseous hydrogen. As a result, a fuel cell truck filled with liquid hydrogen manages with much smaller and, due to the lower pressure, also considerably lighter tanks. This allows for larger cargo space and a higher payload for the trucks. At the same time, more hydrogen can be filled in, which significantly increases the range. Thus, the series of GenH2 trucks, like corresponding conventional diesel trucks, is suitable for long-distance transports that are difficult to plan, multi-day transports where the daily energy throughput is high.

The experts at Daimler Trucks are continuously driving the development of liquid hydrogen tank technologies based on a predefined development plan. The engineers plan to achieve the appropriate level of maturity for the new tank system prototypes by the end of the year to continue the ongoing demanding tests of the GenH2 electric truck. Until it is ready for series production, the vehicle tests are going to be carried out exclusively with liquid hydrogen tank systems. A tank system with gaseous hydrogen will be used as an internal interim solution for the intensive tests of the GenH2 truck that will take place until then. Daimler Trucks has thus demonstrated that both variants - gaseous and liquid - are technically feasible.